3D Printing Advantages and Disadvantages

Advantages and Disadvantages of 3D Printing: A Comprehensive Overview

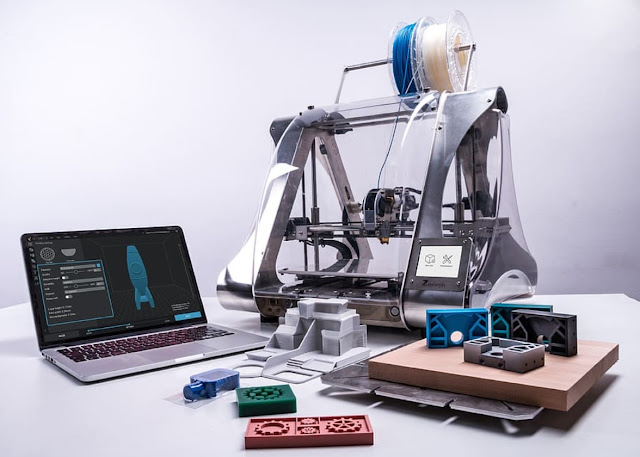

3D printing, also known as additive manufacturing, has revolutionized various industries by offering a unique way to create three-dimensional objects from digital designs. Since its inception, 3D printing technology has evolved significantly and found applications across diverse fields. This article explores the advantages and disadvantages of 3D printing, shedding light on its transformative potential and limitations.

Advantages of 3D Printing

- Design Flexibility and Customization: One of the most significant advantages of 3D printing is its ability to create complex and intricate designs that would be challenging or impossible to produce using traditional manufacturing methods. This allows for high levels of customization, enabling designers to tailor products to specific requirements or individual preferences.

- Rapid Prototyping: 3D printing allows for the quick and cost-effective creation of prototypes. This accelerates the product development cycle, enabling designers to iterate and refine their designs more rapidly, reducing the time to market for new products.

- Reduced Material Waste: Unlike subtractive manufacturing methods, where excess material is often discarded, 3D printing is an additive process that only uses the amount of material needed to create an object. This leads to less waste and more sustainable production.

- Complex Geometries: 3D printing can produce objects with intricate geometries, such as hollow structures, overhangs, and internal cavities, which are difficult to achieve using conventional methods. This opens up new design possibilities for industries like aerospace and healthcare.

- On-Demand Production: With 3D printing, products can be manufactured on demand, reducing the need for large warehouses and minimizing the risk of overproduction. This can lead to more efficient supply chains and reduced inventory costs.

Disadvantages of 3D Printing

- Limited Material Selection: While 3D printing has made significant advancements in available materials, the range still needs to be expanded compared to traditional manufacturing methods. This can restrict the mechanical properties and durability of printed objects.

- Build Size Constraints: The size of objects that can be produced through 3D printing is constrained by the dimensions of the printing equipment. Large-scale manufacturing of objects may require specialized and often expensive machinery.

- Speed and Production Volume: 3D printing can be relatively slow compared to traditional mass-production methods. Producing large items using 3D printing can take time, making it less suitable for high-volume manufacturing.

- Surface Finish and Quality: Depending on the printing technology used, the surface finish of 3D printed objects may not match the smoothness and precision achieved through traditional manufacturing. Additional post-processing steps may be necessary to achieve the desired quality.

- Skill and Expertise Requirements: Successful 3D printing requires specific technical expertise. Designing and optimizing digital models, selecting appropriate materials, and calibrating printers require specialized knowledge and skills.

Conclusion

3D printing has undoubtedly brought about transformative changes in various industries, offering unparalleled design flexibility, rapid prototyping, and reduced material waste. However, it is essential to acknowledge its limitations, such as material constraints, speed, and production volume issues.

Addressing these challenges as technology continues to evolve will likely pave the way for even more widespread adoption of 3D printing across diverse sectors. Balancing its advantages and disadvantages will be vital to unlocking the full potential of this revolutionary manufacturing technology.